Enhancing Surfaces: What is Flash Carbide?

There is a myriad of surface coating solutions on the market that solve many different problems. Hard chrome plating and thermal spray are just two, of many, that are available to industrial manufacturers to resist wear and corrosion damage. For years thermal spray has struggled to compete economically with hard chrome plating for certain industrial applications, namely hydraulic cylinders.

Hard chrome plating has cornered this section of the market by being able to apply thin layers of smooth coating that require little to no finishing, saving time and money over the most comparable thermal spray method, High Velocity Oxy-Fuel (HVOF).

The reason HVOF can’t always compete is largely due to spray material. HVOF can’t accomplish the thin coatings since the powder used to create the coatings must have coarse particle sizes to withstand the heat and velocity of the HVOF application process. This means thicker as-sprayed coatings and causes increased grinding time to meet the required dimensions and surface finish of hydraulic cylinders. Thermal spray just couldn’t compete unless the parts were too large for hard chrome tanks or the operating environment was highly corrosive…until recently.

High Velocity Air Fuel Technology

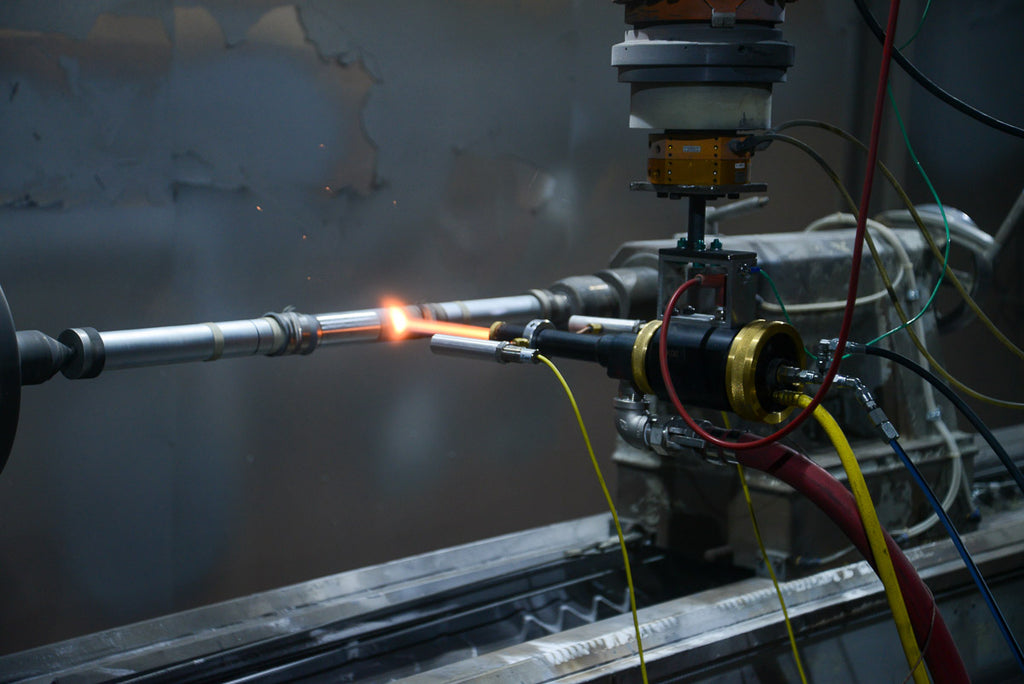

High Velocity Air Fuel, or HVAF, was invented in the late 1990’s to early 2000’s but hasn’t made its way through the market until recently. Using advanced gun technology, HVAF lowers the heat of application allowing for the use of finer cuts of spray material. This gives us the ability to create thin layers of tungsten carbide coating with a lower as-sprayed surface roughness that can be easily finished to OEM dimensions and finishes. This specific type of HVAF coating is known as Flash Carbide.

What is Flash Carbide?

Flash Carbide, a play on the term Flash Chrome, is a thermal spray coating that is applied quickly with minimal prep and finishing due to advances in the gun technology. These coatings can outperform hard chrome plating in certain situations. The HVAF technology also creates harder yet more well bonded coatings. For more information on how HVAF coatings and Hard Chrome Plating compare on issues like hardness, bond strength and cracking check out the other blog post in our Enhancing Surfaces series.

Flash Forward

So while Flash Carbide is not a materials-based, speedy comic book superhero, it is a great solution for hydraulic cylinder remanufacturers, or anyone else, who is experiencing rising chrome prices. There may even be performance benefits that outweigh hard chrome even if the cost was a little more in certain situations. Flash Carbide can keep your rods and cylinders running stronger for longer. But it doesn’t stop there, HVAF technology can be used in many different ways on many different industrial components to prevent wear, corrosion, and even cavitation damage for pumps.

Just like every other surface solution out there, there are going to be areas where one excels over the other. The important thing is to do your research, talk with a trusted coating provider who will be honest about their applications and limitations, and every once in a while, give something else a try to see if it could enhance the life of your components.

Contact us today about enhancing the life of your industrial components:

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.