Three Common Types of Ceramic Thermal Spray Coatings

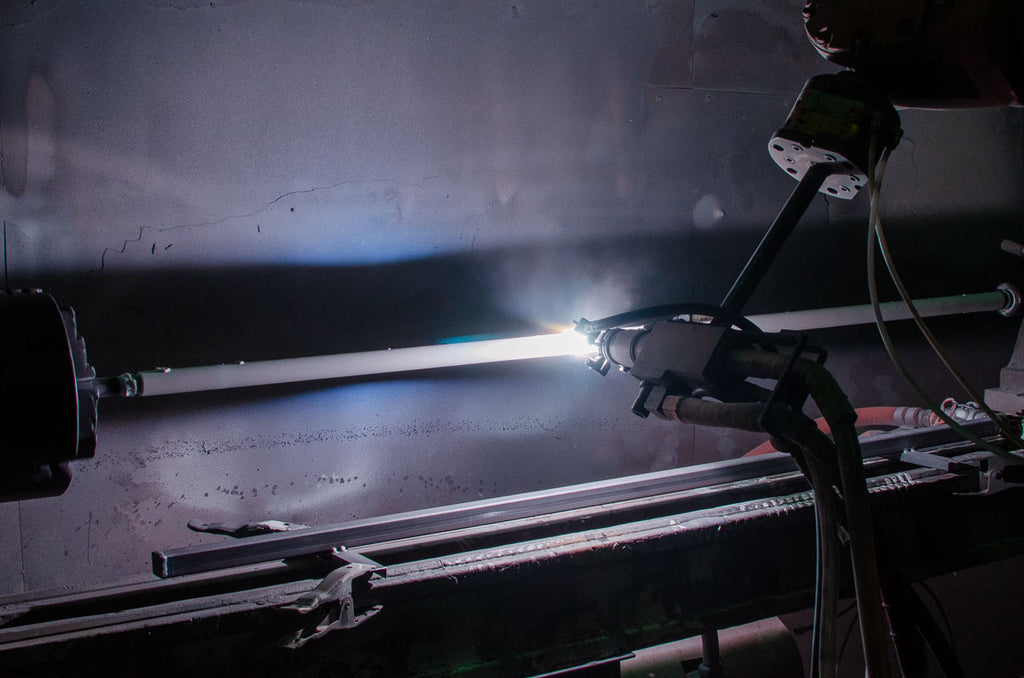

Each thermal spray process has a few materials that it is really good at applying. There are also some coating materials that can only be applied by certain processes. One of those coating categories is ceramic thermal spray coatings. Due to the high melting point of ceramics, it requires a very hot thermal spray process to apply them. The only thermal spray process that fits that bill is plasma thermal spray. Plasma spray uses an electrical arc to dissociate and ionize hydrogen and argon gases. This creates a maximum flame temperature of around 12,000-35,500°F. For reference, the next hottest thermal spray process, twin-wire arc spray, only gets up to 7,000°F. The ceramic coating powder is then injected into this stream and applied to the surface of a part. Three common ceramic coatings are chrome oxide, aluminum oxide, and titanium dioxide.

Chrome Oxide Coating

Chrome oxide is our most requested ceramic coating. Chrome oxide coatings come in a variety of chemical formulations that accent various strengths. To keep things brief, we will stick to chrome oxide coatings as a whole. Chrome oxide coatings are generally selected for their wear resistance to chemical exposure. It is wear resistant up to 1000°F in most cases and up to 350-400°F in corrosive chemical environments. It has the highest wear resistance of the ceramic coatings. It is commonly used for sealing surfaces in pumps, textile rolls and food processing equipment.

Chrome oxide coatings have a hardness of 62-70 Rockwell C; depending upon the chemical formulation. They can typically be applied anywhere from 0.003” to 0.025” thick. The best surface finish possible with grinding and polishing is an 8 Ra-in but a better surface finish can oftentimes be achieved with superfinishing. It is the best combination of hardness and smoothness but can be costly compared to other ceramic coatings.

Aluminum Oxide Coating

Another beneficial ceramic coating is aluminum oxide or alumina. This coating is most selected for its dielectric and thermal barrier properties. It is wear and heat resistant up to 3000°F. It’s dielectric strength is estimated to be around 300 to 400 volts per 0.001” of thickness at room temperature. It can withstand exposure to the aqueous alkali solutions in some industrial cleaners such as lye, ammonia, and nonphosphate detergents. It is commonly used in motor housings, liners, pump seals and for non-conductive rollers. It also has a low coefficient of friction compared to other ceramic coatings.

Alumina thermal spray coatings have a hardness of 60-66 Rockwell C and can be applied anywhere from 0.005” to 0.020” thick. One limitation of aluminum oxide is surface roughness. It typically can only be finished down to 20 Ra-in which, while good, is higher than other ceramic coatings. Both, chrome oxide and aluminum oxide, can be on the premium side of thermal spray coating materials. If budget is a concern, you may want to consider titanium dioxide.

Titanium Dioxide Coating

Titanium dioxide can be easier on the budget and a decent solution in moderate wear environments up to 1000°F. It has good corrosion resistance except in the presence of alkalis and sulfuric acid. It is best in sliding wear situations and for wear from abrasive grains. It has a hardness of 50-53 Rockwell C and can typically be applied anywhere from 0.005” to 0.025” thick. It can achieve a surface roughness down to 8 Ra-in. If you are looking for the smoothness of chrome oxide but not worried as much about hardness, titanium dioxide can be a cost effective alternative to chrome and other ceramic coatings. For this reason, it earns its place in our three most common ceramic coatings.

Which Ceramic Coating is the Best Fit?

If you are looking for a coating to resist wear and chemical corrosion with a smooth surface finish, chrome oxide is your best bet. If you want some chemical corrosion and surface roughness benefits without some of the cost and aren’t worried so much about wear, you can try titanium dioxide. If you are after a dielectric coating or a thermal barrier coating, then you can go with an aluminum oxide. Each ceramic coating, including the ones not mentioned here, is valuable for one purpose or another. The best way to choose what is right for you is to look at the problems you are trying to solve with your coating and do lots of research or reach out to a trusted thermal spray company for a recommendation.

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.