Service Environment: The Limits of Thermal Spray Coatings

(Part 3 of 3)

Thermal spray coatings have many benefits. From wear and corrosion resistance to dimensional restoration, it can fit into many manufacturing and maintenance initiatives. Unfortunately, there are some environments where thermal spray coatings are not a good fit. Along with part geometry and coating thickness, there are environmental limits such as abrasion, loading, and service temperature for thermal spray coatings.

Abrasive Environments

There are many different types of wear that a part can experience. Thermal spray coatings aren’t a fit for all of them. Thermal spray coatings are mechanically bonded. This means they are held onto the part by the internal stresses and the frictional stresses between the coating particles and the surface. This works great in sliding, rotating, and galling wear. On the other hand, in some environments, like impact or point loading, the coating could crack and chip off. For example, ones where rocks would hit the coating surface, especially on an edge. Another example of environmental limitations is bending or tension loading.

Bending and Tension Load Environments

One thing that contributes to the wear resistance of thermal spray coatings is their hardness. But this also means that they are not as ductile. Any bending load or flexion will inevitably crack the coating. In the same vein, anything that pulls on the coating could potentially pop the coating off. Depending on the type of thermal spray process used, the coatings can handle anywhere from 1,000 to over 10,000 psi pull strength. Flame and Arc spray processes fall on the low end of this range while plasma, HVOF, and HVAF will land on the higher end depending on the coating material. Not only should you look out for incompatible loading scenarios, but the service temperature of the part can also limit whether a thermal spray coating is a good fit.

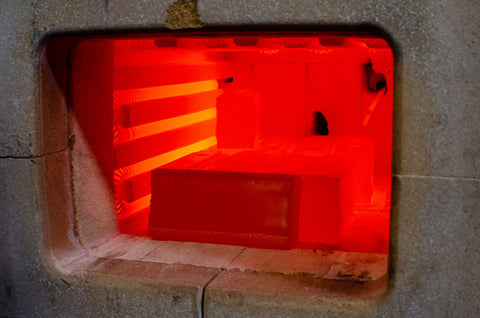

Service Temperature

While not often, we do run into this limitation in specialized situations. When we say, service temperature, we mean the temperatures and temperature cycling the parts will see when in operation. This limitation will also vary by coating composition. On the lower end are your metallic alloys; they can typically withstand up to 500-800 °F. Some specialized ceramic materials can be used at temperatures up to 2000 °F. There are some non-ceramic coatings, such as Hastelloy C-276, that can safely operate up to 1800 °F. There are less common thermal spray materials that can withstand higher, but they are not readily available materials and are usually much more expensive than standard thermal spray coatings.

After these temperatures, you begin losing wear and corrosion resistance reliability, as well as risking total coating failure. Another less common concern is thermocycling. If a part sees large spikes in temperature in a very short amount of time, it could cause the coating to fail and come off. This rarely happens but is something to be aware of when considering a thermal spray coating.

An example would be welding on a coating after it has been applied. Adding high heat near the coating or heat that causes the substrate to shrink will cause the coating to come off. We typically recommend leaving at least 0.5” space between any thermal spray coating and a weld that will be done after coating. On a related note, all heat treating should also be done prior to thermal spray coating, except in cases of spray and fuse, or a coating failure will occur.

If Thermal Spray Doesn't Fit, Don't Force It

While these environments aren’t always thermal spray friendly, plenty of environments are. The limiting factors of thermal spray all come down to the bonding mechanism. These environments require a metallurgical bond and would be great candidates for other coating processes such as spray and fuse or hardface welding.

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.